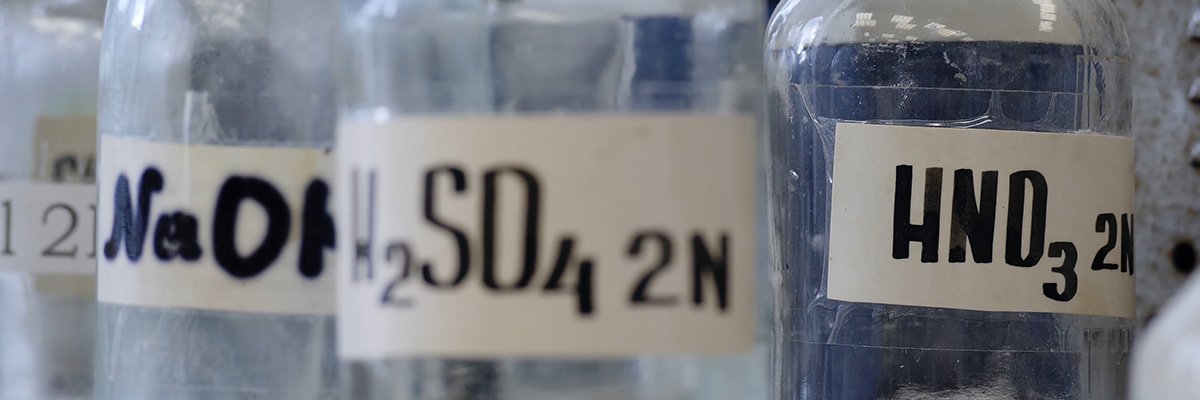

When a chemical product comes clearly labelled with hazard symbols and safety data, it’s easy to assume that’s enough. But even if a substance is properly packaged and carries the correct warning signs, that alone does not mean it’s safe to use — or that you’re compliant with the Control of Substances Hazardous to Health (COSHH) Regulations 2002.

In this article, we explain why hazard labels and supplier information are only part of the picture, and why every business still needs to carry out its own COSHH assessments to protect workers and meet legal requirements.

The Purpose of Labelling and Safety Data Sheets (SDS)

Manufacturers and suppliers are legally required to label hazardous substances in accordance with the Classification, Labelling and Packaging (CLP) regulations. This includes:

-

Hazard symbols and signal words (e.g. Danger, Warning)

-

Precautionary statements

-

First aid and storage instructions

-

A Safety Data Sheet with detailed information

This information helps users understand the general risks associated with the substance — but it’s not tailored to your workplace, your staff, or your specific processes.

COSHH Requires a Workplace-Specific Assessment

Under COSHH, employers must assess the actual risks posed by hazardous substances in their particular environment. This includes:

-

How the substance is used (e.g. sprayed, brushed, heated)

-

Who is exposed and for how long

-

What control measures are already in place

-

How the substance is stored, transferred, and disposed of

-

Emergency procedures for spills or exposure

Even if a product is labelled correctly, you must carry out a COSHH risk assessment to evaluate how it’s used on your premises and what steps are needed to reduce harm.

Real-World Examples

-

A cleaning chemical that’s safe when diluted in water may cause harm if sprayed in a small, poorly ventilated space.

-

A flour bag in a bakery carries no hazard label, but repeated exposure to airborne flour dust can cause occupational asthma.

-

A solvent may be labelled flammable and harmful, but your COSHH assessment reveals that it’s being used near heat sources, creating an additional fire risk.

Without a tailored risk assessment, these risks could easily go unnoticed.

What Your COSHH Assessment Should Cover

To go beyond the label, your assessment should:

-

Identify all hazardous substances used or generated on-site

-

Understand how employees may be exposed (inhalation, skin contact, ingestion)

-

Evaluate the health risks based on actual use

-

Implement control measures to reduce or eliminate exposure

-

Provide training and information to staff

-

Monitor effectiveness and review assessments regularly

Your findings should be clearly documented, communicated to staff, and regularly updated.

The Consequences of Skipping the Assessment

Relying on labelling alone, without conducting a full COSHH assessment, can lead to:

-

Breaches of health and safety law

-

Exposure-related illnesses such as asthma, dermatitis, or chemical burns

-

HSE enforcement action, fines, or prosecution

-

Insurance claims being denied due to lack of documentation

-

Damage to your company’s reputation

Final Thoughts

Labels are an important first step in understanding chemical hazards — but they are not a substitute for a workplace-specific COSHH risk assessment. Every business, no matter how small, must take ownership of how hazardous substances are used and controlled on-site.

At SIS Ltd, we support organisations with independent COSHH assessments, practical advice, and compliance support tailored to your operations. If you’re not sure whether your current approach meets the requirements, we’re here to help you get it right.